The environment

Energy Efficiency

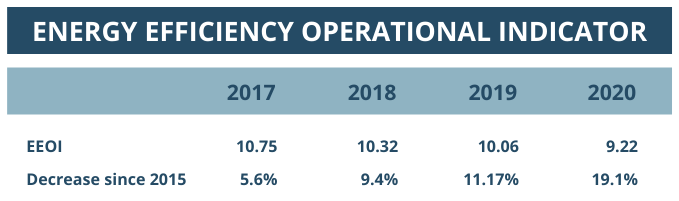

Since 2015, a primary focus area has been to improve the energy efficiency of the fleet. All vessels in the fleet are now equipped with sensor technology to measure and monitor fuel performance. Propeller boss cap fins, which enhance the effect of the propeller, are standard on vessels suitable for this technology. Advanced Biofouling is applied to the hulls of most of the vessels in the fleet and they undergo regular hull cleaning and propeller polishing to maintain their efficiency.

CO2 Emissions

Since 2010 Gearbulk has closely monitored the carbon dioxide emissions from the fleet. The index utilized is the Energy Efficiency Operational Indicator (EEOI), defined as the mass of CO2 emitted (in grams) when moving one metric tonne of cargo one nautical mile. It is calculated using IMO guidelines for all trades including ballast voyages but excluding fuel used under pilotage and in port.

Carbon dioxide emission control is directly related to energy efficiency, and the EEOI has seen a significant drop since 2015. Any further reduction in emissions will be a combination of a fuel-efficient operational profile and technical improvements in our existing fleet.

Regulation 22.2 of MARPOL Annex VI came into force on 31st December 2018 which includes a new Part II of the SEEMP, the Ship Fuel Oil Consumption Data Collection Plan. All managed vessels are now SEEMP II compliant.

Gearbulk welcomes tighter regulations which are essential in reducing our ecological footprint so that we can develop into a sustainable industry while continuing to serve the world economy.

IMO Emission Target

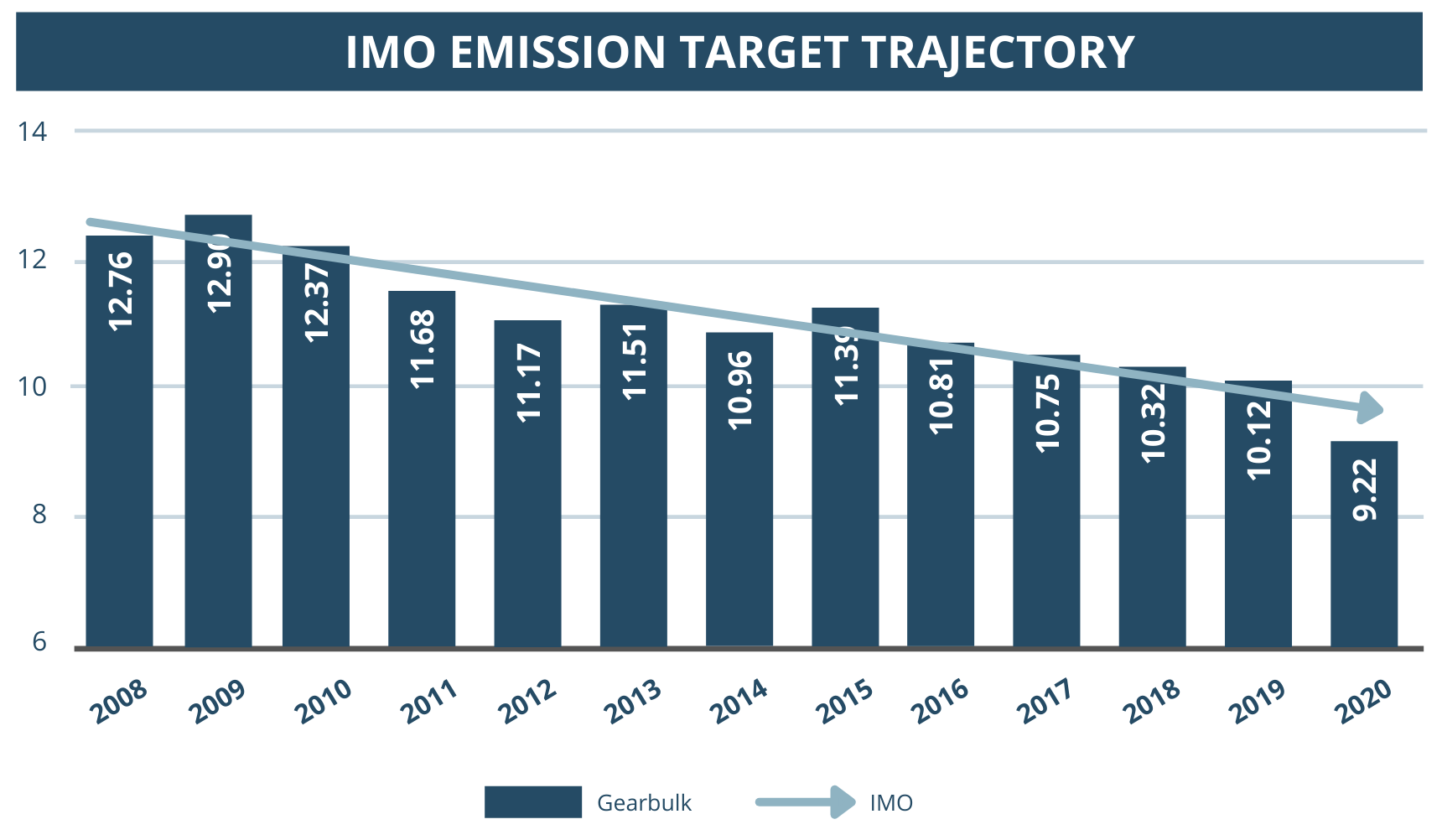

IMO GHG Strategy adopted in 2018 sets ambitious targets to halve GHG emission from ships by 2050 compared to 2008, and reduce carbon intensity of international shipping by 40% by 2030 compared to 2008.

The Company is to-date in compliance with the IMO target. Continued decline in emission assuming constant fuel consumption will mainly be possible with the induction of more fuel-efficient ships in future replacing older tonnage and less efficient tonnage.

The performance of the managed fleet since 2008 is shown in the graph below.

Poseidon Principles

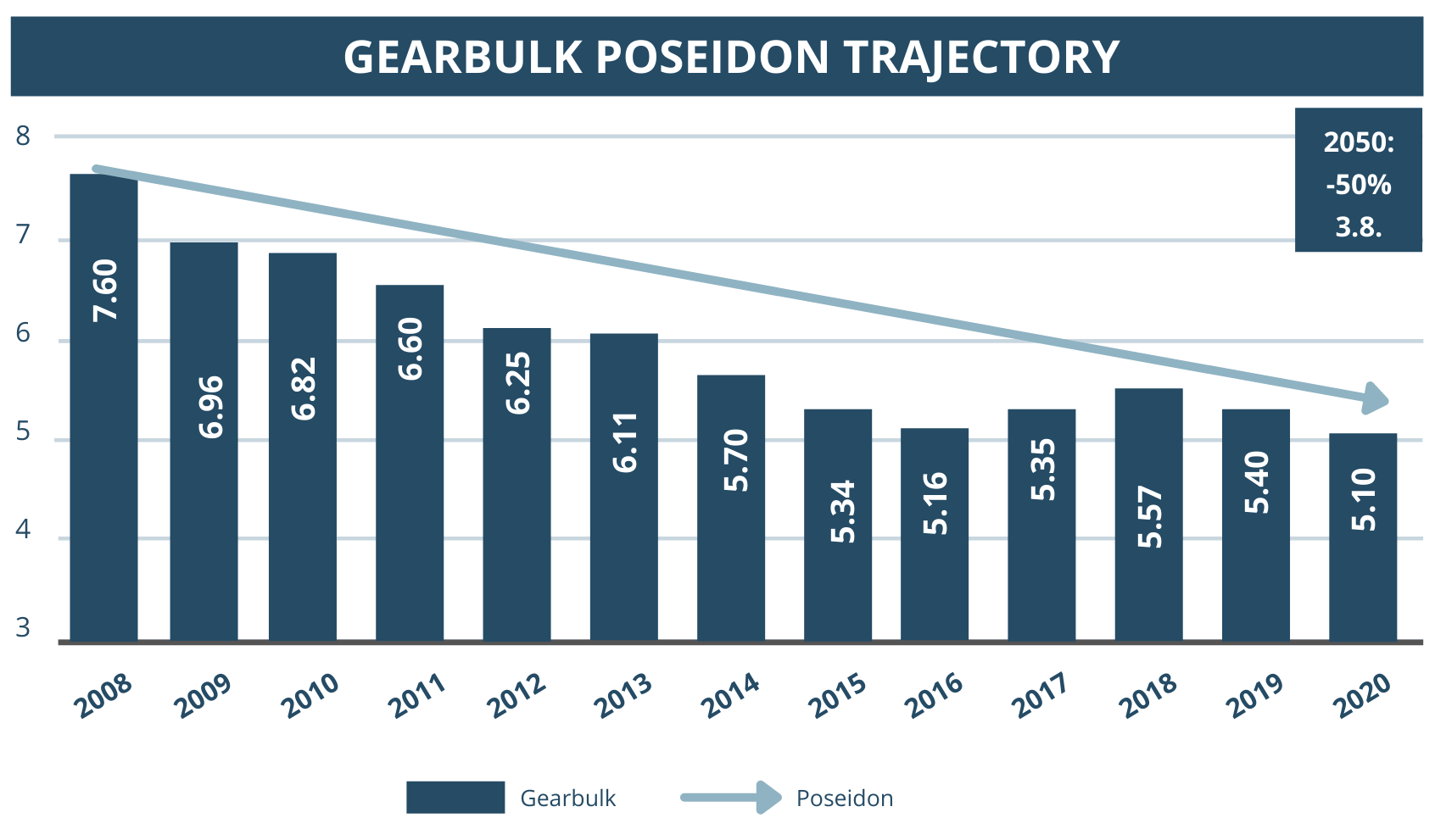

In June 2019, financial institutions launched a global framework for ship finance, named the “Poseidon Principles”. These Principles are claimed to be consistent with the policies and ambitions of the IMO, including for greenhouse gas (GHG) emissions to peak as soon as possible and to reduce shipping’s total annual greenhouse gas emissions by at least 50% by 2050 compared to 2008.

Signatories are required to measure the carbon intensity on an annual basis and assess climate alignment of their shipping portfolios.

Carbon intensity as has been reported by the Company represents the total operational emissions in real operating conditions generated to satisfy a supply of transport work (grams of CO2 per tonne-nautical mile [gCO2/t-nm]).

The IMO also uses another metric known as the “Average Efficiency Ratio” that uses the design deadweight instead of the actual cargo carried on board. Poseidon Principles uses a metric known as the “Annual Energy Ratio” (AER) that is similar to the IMO Average Efficiency Ratio, where Ci is the carbon emissions for voyage i computed using the fuel consumption and carbon factor of each type of fuel, dwt is the design deadweight of the vessel, and Di is the distance travelled on voyage I, computed for all voyages performed over a calendar year.

This metric is compared with decarbonisation targets assigned according to ship type and deadweight tonnage, with the target getting more stringent every year.

The Poseidon trajectory of the managed fleet since 2008 is below.

Sulphur and Nitrous Oxides

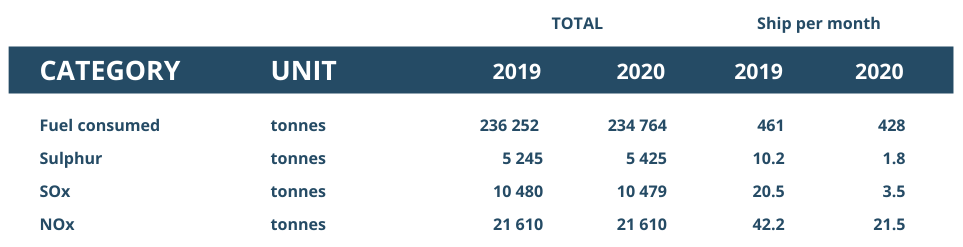

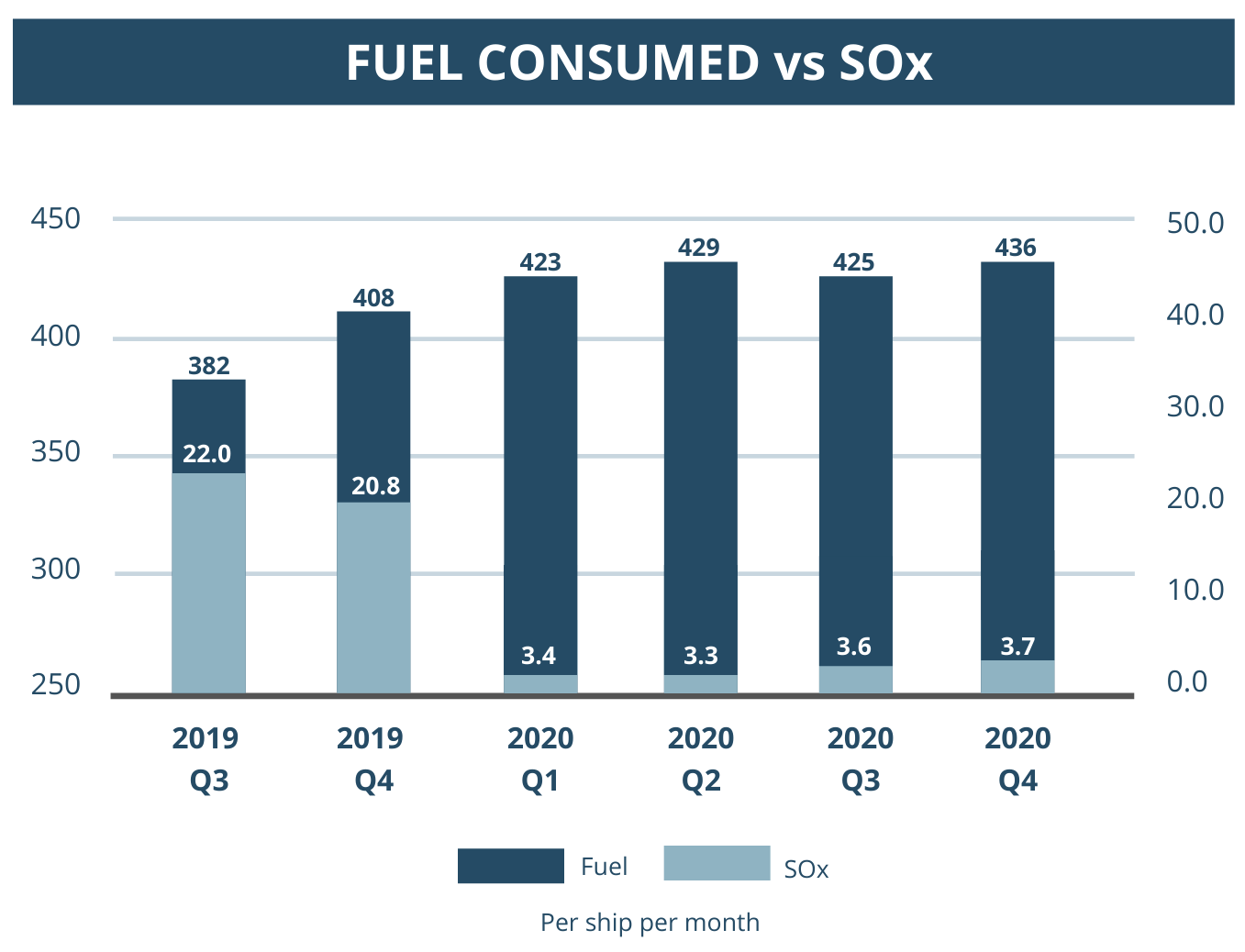

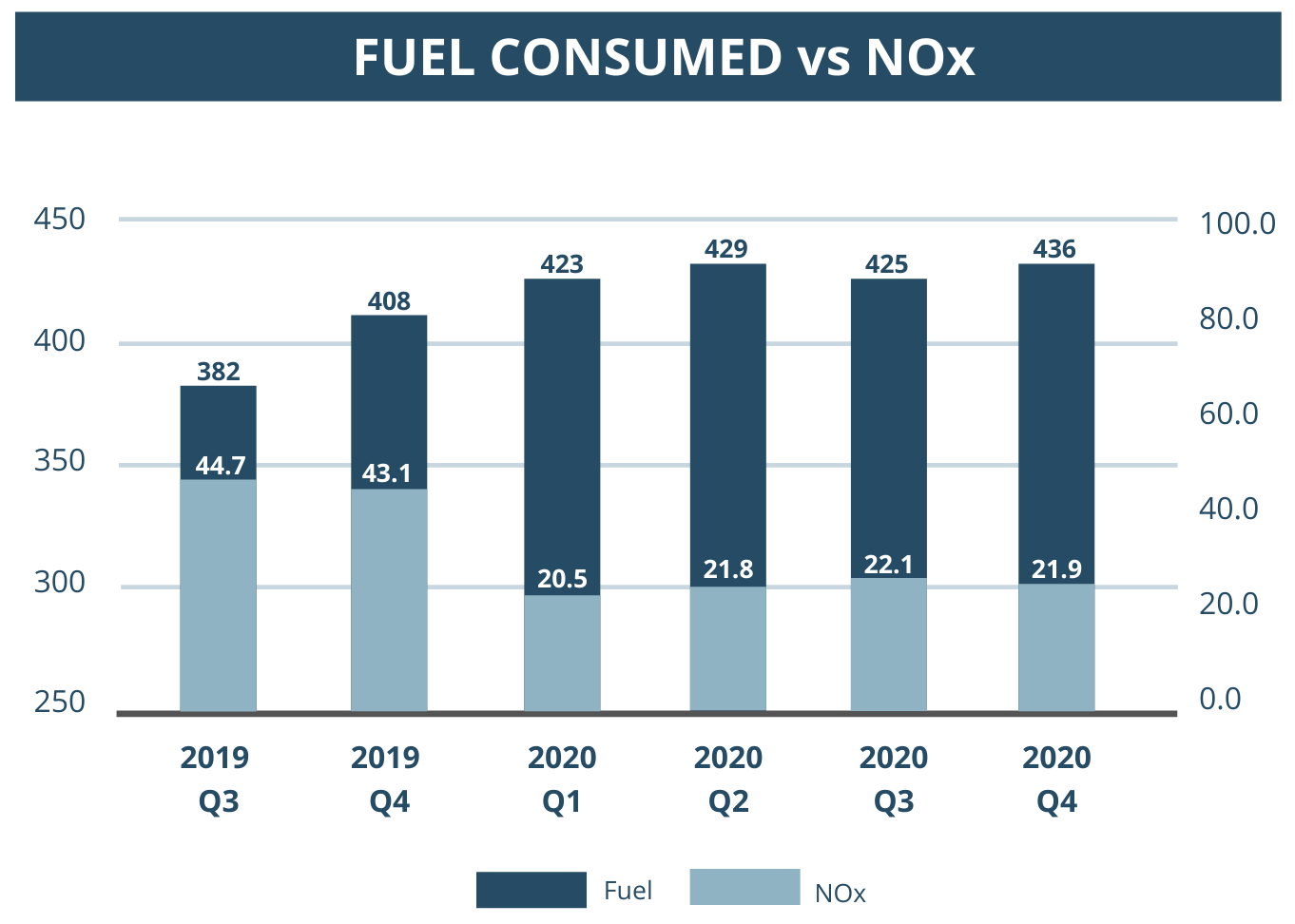

SOx emission has shown a major decrease with the changeover to very low sulphur content fuel. NOx emission has halved since 2019. NOx emission from ships without NOX rated main engines continue to be estimated based on the SOx emission.

Starting in 2019, the method of calculation for ships with a stated NOx emission cycle E3 value for their main engine is based on that value. For ships without this value, it remains an estimate based on the SOx emitted.

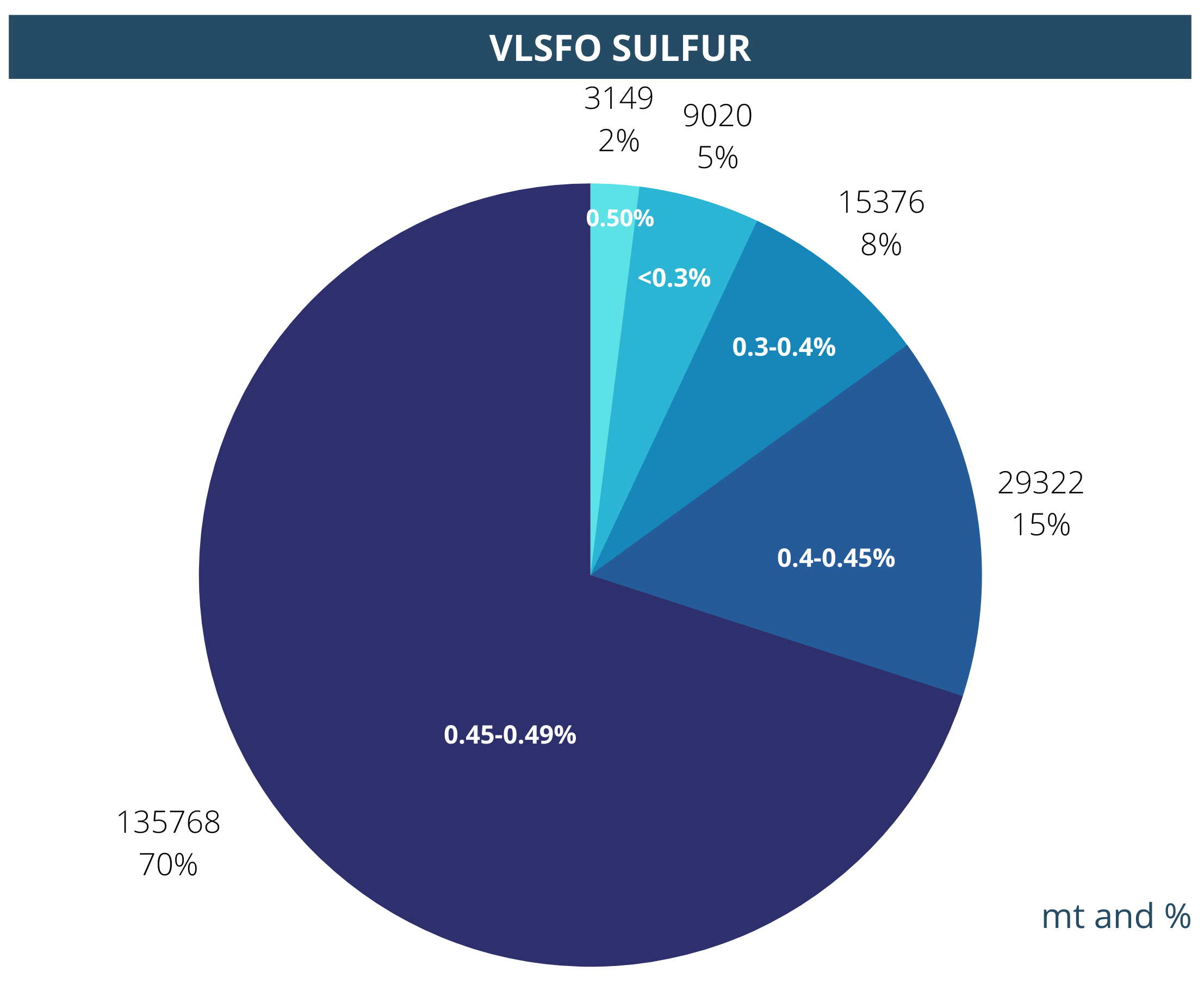

Sulphur content of bunker fuel

IMO MARPOL Annex VI regulation on limiting sulphur content of bunker fuel to a maximum of 0.5% came into force on 01/01/2020. Shown below is the breakup of VLSFO consumed by sulphur percentage based on the BDN.

The average sulphur content of the fuel supplied in 2019 was 2.23% while it was 0.41% in 2020, an 81% drop.

The Company issued circular, SMS 0401.15.37 – Use of VLSFO to guide seafarers in the use of the new VLSFO that mostly consists of blended fuel.

Oil Pollution

In 2019 there were three minor incidents involving Gearbulk owned vessels. All incidents were a result of compromised hydraulic hoses.

Target

The target of the company is to have no oil spills outside the vessel.

Office Initiatives

Gearbulk concentrates on two main areas for its shore-based personnel; general office waste and use of electricity. Offices are fitted with motion sensitive lighting and automatic power down equipment. All personnel are encouraged to segregate office waste, monitor paper usage and look for ways of reducing their impact on the environment in all areas of business and personal life.

There has been a sharp drop in the consumption of paper due to a reduction in staff and a significant reduction in printing of manuals mandatory for the vessels which required official stamps and Class approval. The focus is on minimising usage and recycling paper and plastic.

Other areas that each office looks at are how employees can reduce, reuse and recycle office equipment, old computers, batteries and printer cartridges. All offices and staff are encouraged to recycle as much as they can although this is not always easy in every country that Gearbulk operates due to lack of recycling facilities.