The environment

Energy Efficiency

Since 2015, a primary focus area has been to improve the energy efficiency of the fleet. All vessels in the fleet are now equipped with sensor technology to measure and monitor fuel performance. Propeller boss cap fins, which enhance the effect of the propeller, are standard on vessels suitable for this technology. Advanced Biofouling is applied to the hulls of most of the vessels in the fleet.

Oil Pollution

In 2019 there were zero incidents involving Gearbulk owned vessels.

Target

The target of the company is to have no oil spills outside the vessel.

Fuel oil sludge

This is the oily waste created from burning fuel on board vessels. There are strict rules on how this is discharged from vessels, and Gearbulk must ensure that that our vessels do not pollute the oceans with this.

4,108 metric tonnes of sludge were discharged ashore compared to 4,887 metric tonnes in 2018, a decrease of 16%. This proves that focus on utilising the evaporation systems fitted onboard will improve the impact on the environment and also have a positive economic impact.

Target

Vessels must work towards increasing the quantity of sludge evaporated on board to meet the environmental objective of 50% by the end of 2020.

CO2 Emissions

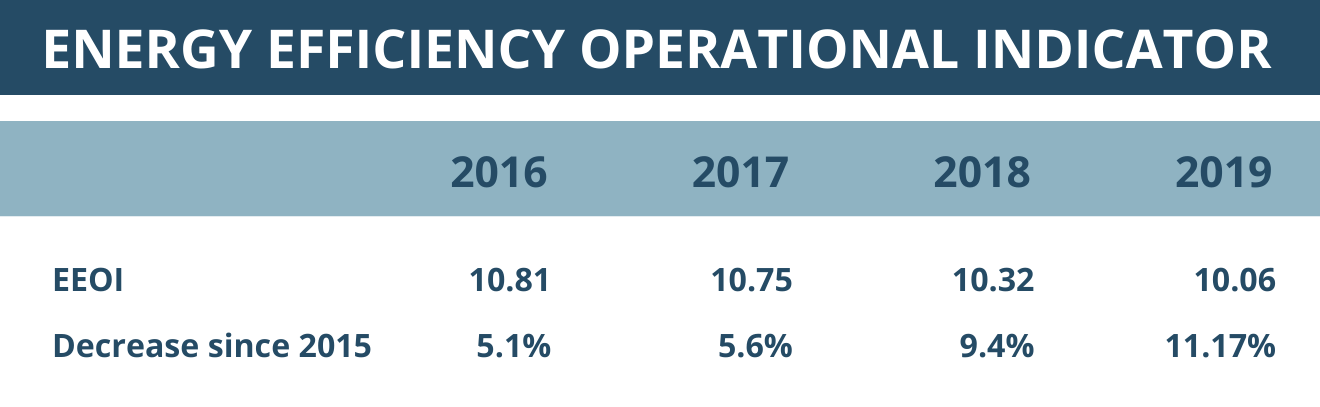

Since 2010 Gearbulk has closely monitored the carbon dioxide emissions from the fleet. The index utilized is the Energy Efficiency Operational Indicator (EEOI), defined as the mass of CO2 emitted (in grams) when moving one metric tonne of cargo one nautical mile. It is calculated using IMO guidelines for all trades including ballast voyages but excluding fuel used under pilotage and in port.

Carbon dioxide emission control is directly related to energy efficiency, and the EEOI has seen a significant drop since 2015. Any further reduction in emissions will be a combination of a fuel-efficient operational profile and technical improvements in our existing fleet.

Regulation 22.2 of MARPOL Annex VI came into force on 31st December 2018 which includes a new Part II of the SEEMP, the Ship Fuel Oil Consumption Data Collection Plan. All managed vessels are now SEEMP II compliant.

Gearbulk welcomes tighter regulations which are essential in reducing our ecological footprint so that we can develop into a sustainable industry while continuing to serve the world economy.

Target

The target of the Company is to achieve a 4% reduction in EEOI from 2015 levels by end of 2020.

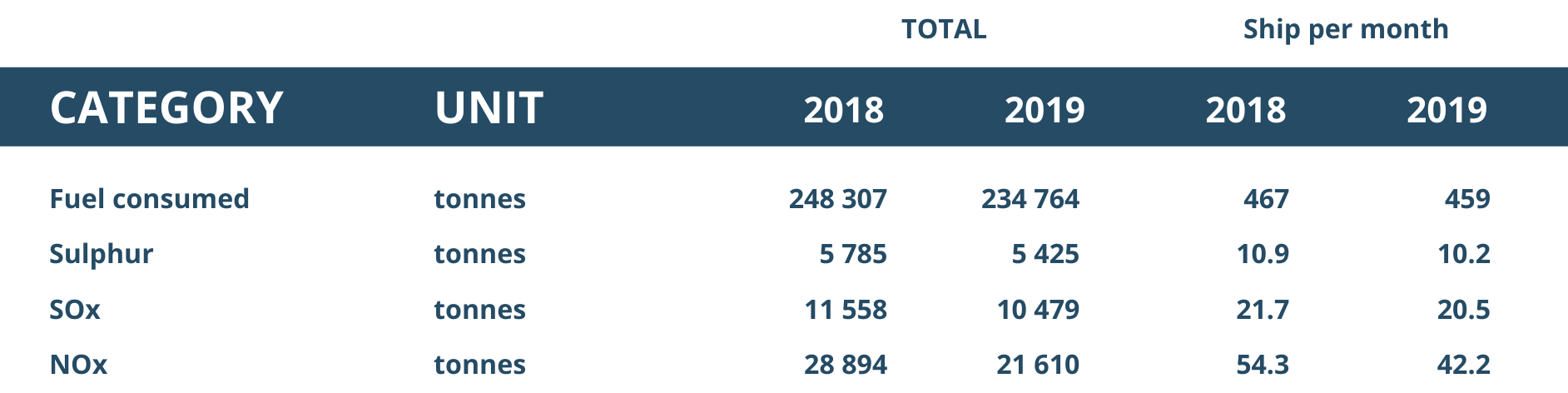

Sulphur Emissions

A greater part of the year was spent preparing the fleet for the 2020 Sulphur Cap regulation, where Gearbulk opted for Very Low Sulphur Fuel Oil (VLSFO) consumption for our vessels. This required tank cleaning, lube oil changes and consumption and safe de-bunkering of excess old high sulphur bunkers. By 31st December 2019, all Gearbulk vessels were compliant to the new regulations.

IMO MARPOL Annex VI regulation on limiting sulphur content of bunker fuel to a maximum of 0.5% will come into force on 1st January 2020. At present, the global sulphur content cap on bunker fuel is at 3.5%.

Nitrogen Oxide Emissions

Nitrogen oxides (NOx) are formed by high temperature during the combustion process. NOx causes acid rain, affects human health and contributes to global warming.

All vessels delivered since January 2011 are compliant with MARPOL Annex VI regulations.

Starting in 2019, the method of calculation for ships with a stated NOx emission cycle E3 value for their main engine is based on that value. For ships without this value, it remains an estimate based on the SOx emitted.

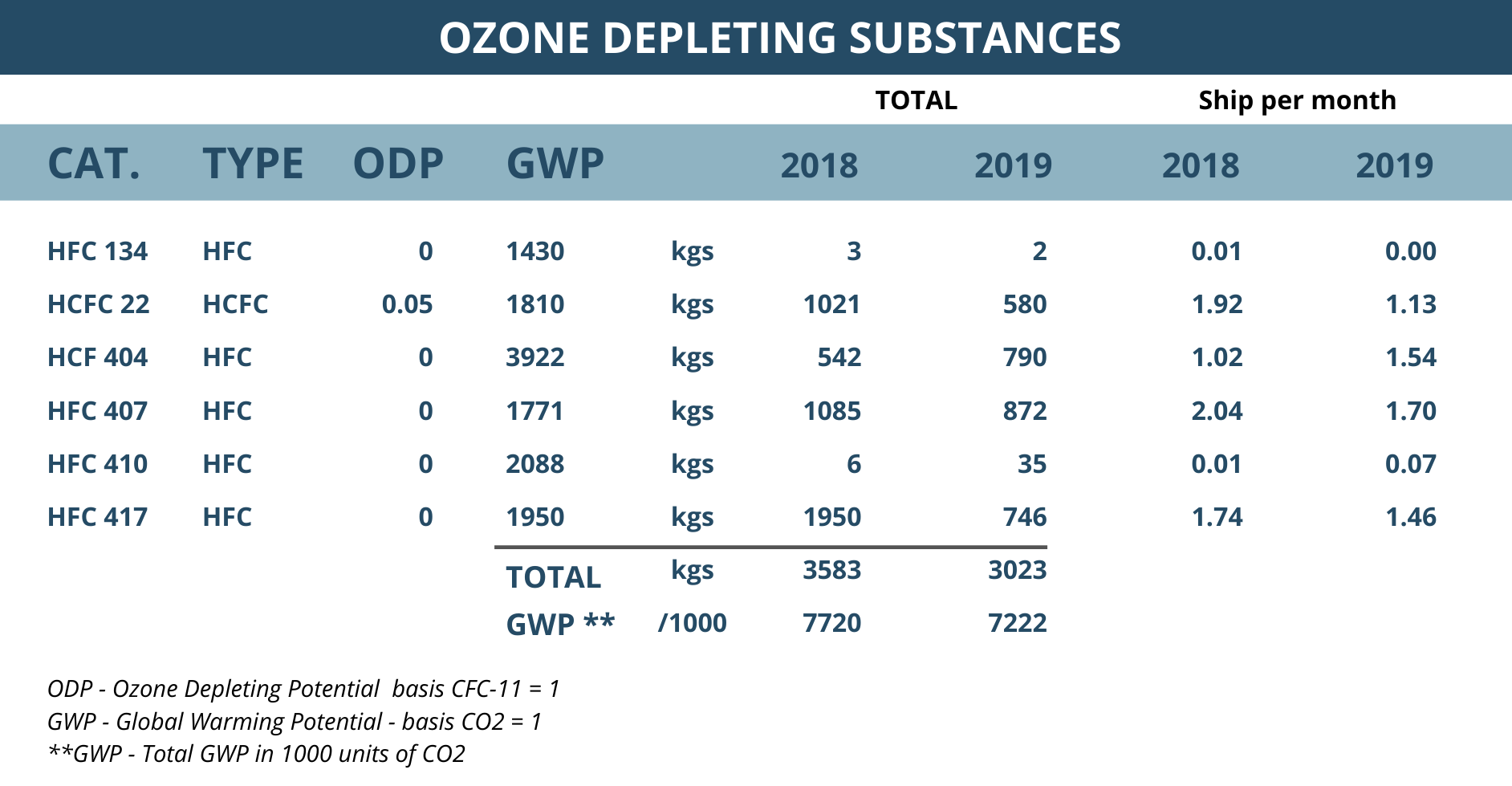

Pollution from Ozone Depleting Substances

Detailed measurements have been kept for the whole fleet, highlighting vessels with older equipment onboard that will need replacing to ensure that Gearbulk is not emitting ozone depleting substances. An increased focus on preventive maintenance led to a reduction of (all) released gases by 15,5% compared to 2018.

Target

The target was to eliminate the use of R-12 and R-22 gas on board the vessels by the end of 2018. Use of R-12 has been eliminated but in the case of R-22, elimination was not achieved due to vessel scheduling and some vessels nearing the end of their life.

Office Initiatives

Gearbulk concentrates on two main areas for its shore-based personnel; general office waste and use of electricity. Offices are fitted with motion sensitive lighting and automatic power down equipment. All personnel are encouraged to segregate office waste, monitor paper usage and look for ways of reducing their impact on the environment in all areas of business and personal life.

There has been a sharp drop in the consumption of paper due to a reduction in staff and a significant reduction in printing of manuals mandatory for the vessels which required official stamps and Class approval. The focus is on minimising usage and recycling paper and plastic.

Other areas that each office looks at are how employees can reduce, reuse and recycle office equipment, old computers, batteries and printer cartridges. All offices and staff are encouraged to recycle as much as they can although this is not always easy in every country that Gearbulk operates due to lack of recycling facilities.